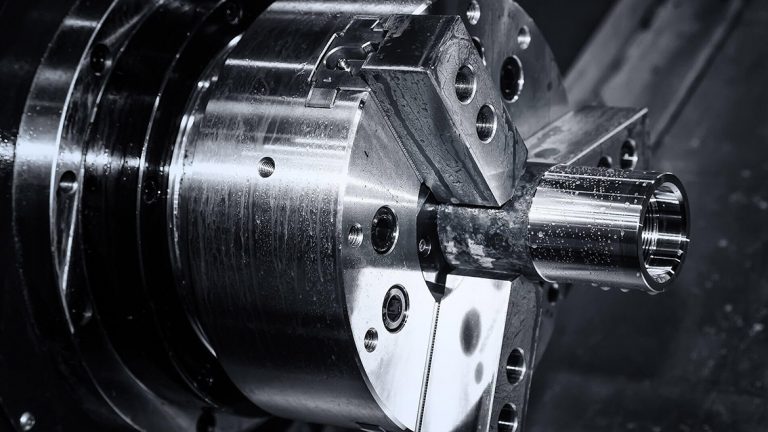

CNC Turning

Turning is a machining process used to create external surfaces of parts with a circular

cross-section.

In a lathe machine, the workpiece rotates around its axis while a tool moves

perpendicularly, removing material with a steady feed rate.

Turning refers to machining external surfaces, while boring is used for machining internal

circular surfaces.

During this process, the workpiece rotates around its axis while the tool or workpiece moves

perpendicularly with a consistent feed rate to remove material.

CNC Turning at DM Laser Industrial Group

CNC lathes are machine tools used for shaping and machining wooden and metal parts, typically cylindrical ones.

Due to their economical production with high accuracy and quality, lathes are available in various forms and designs. Most machine parts have circular cross-sections that can be produced with lathes. Additionally, turning is widely used in the industry for its low cost and high speed compared to other methods. The primary function of a lathe is to modify the size, shape, and finish of parts through one or more cutting actions, using adjustable cutting tools.

By equipping lathes with auxiliary tools and devices, their range of activities is

significantly expanded.

Operations such as reaming, threading, and drilling can be easily performed on a lathe with

appropriate tools.

In general, the basic principles of lathes are based on the concept of metal turning.

During turning operations, material is removed by the cutting edge of the tool, moving the

chips along the rake surface.

In all machining operations like turning, drilling, milling, or sawing, chips are generated.

A force of 20 tons per square inch is applied during this process, causing the metal to

deform and generate heat.

The movement of chips along the cutting surface results in friction, producing heat at the

cutting edge, a crucial factor in material removal.

CNC lathes are highly valuable due to their CNC-controlled capabilities for precise and

complex shaping.

DM Laser Industrial Group, with its experienced machining specialists and a workshop equipped with modern tools and machines, is capable of executing turning and milling projects using manual lathes, NC lathes, and CNC lathes with high accuracy and quality.

Types of CNC Lathes

CNC lathes come in various types, and here are a few examples.

Linear Horizontal CNC Lathe:

In this lathe, axis movement is guided by rails and wagons. Advantages: high-speed movement, long lifespan, easy maintenance.

BoxWay CNC Lathe:

In this lathe, axis movement is guided by Turcite. Advantages: higher load capacity and longer lifespan.

Multi-Axis Multi-Function CNC Lathe - MultiTurret Q200:

This lathe features 11 axes and 3 turrets that work simultaneously on the workpiece.

Multi-Axis Horizontal CNC Lathe - Vturn X200:

This lathe has two spindles and 9 axes, with additional milling capabilities.

Gang Type CNC Lathe

Swiss Type CNC Lathe

Turning Processes

Turning

Turning is one of the fundamental machining processes where the workpiece rotates while a single-point cutting tool moves parallel to the rotation axis. It can be performed on the internal or external surface of the workpiece. Typically, the workpiece is produced through casting, forging, or extrusion before machining.

Taper Turning

This process is performed using a compound slide and involves taper turning with hydraulic copying attachments or CNC machines.

Grooving

In the grooving process, the grooving tool gradually moves radially into the workpiece, creating grooves equal to the tool width on the cylindrical surface.

Thread Cutting

For thread cutting with a lathe, threading tools are used. These tools must match the thread profile, and with specialized attachments or lead screws, threading is performed.

Knurling

Knurling creates uniform, patterned grooves on the workpiece's surface.

Types of Lathes

Lathes are widely used for turning operations and are available in various types.

Horizontal and vertical lathes are among the most common types.

Most lathes are rotary with rotating tool holders.

Semi-automatic lathes are prevalent, with CNC lathes being the most advanced type.

Center Lathe

Center lathes are conventional machines featuring key components such as:

- Tailstock

- DC Motor

- Headstock

- Bed

- Tool Post

- Saddle

Copying Lathe

Copying lathes can produce identical parts from a sample using hydraulic or electronic systems. The tool path follows the sample's surface, much like key-making machines. These lathes are often used in woodworking and furniture production.

Vertical Lathe

Vertical lathes feature a rotating table where heavy or large parts are clamped securely.

The workpiece rotates with the table, and machining occurs as the tool engages the material.

These lathes are ideal for facing and turning large, heavy parts.