Stainless Steel Laser Cutting

Overview of Stainless Steel Laser Cutting

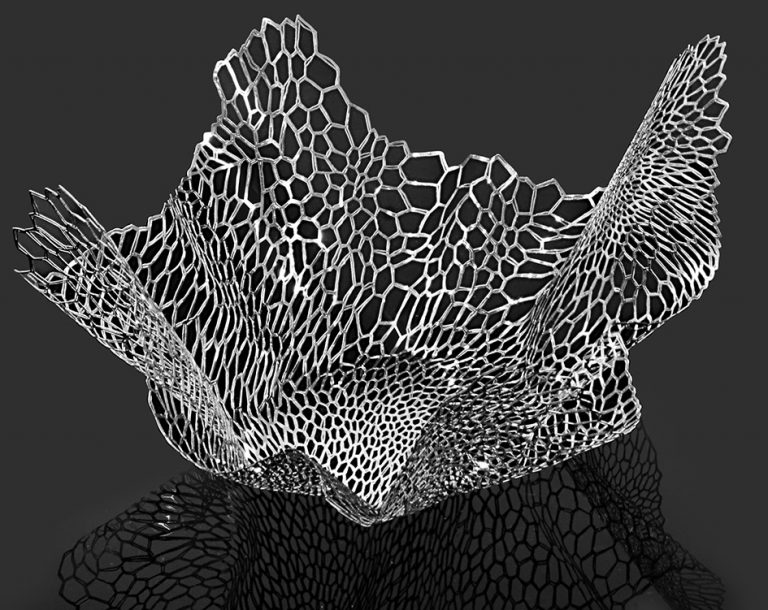

Laser cutting is widely used today in many industries, from manufacturing to medicine. One of its applications in the industry is cutting various materials with lasers. One such material is stainless steel. Any stainless steel object that needs to be cut into various shapes and pieces can be done through laser cutting. Laser cutting works by directing a powerful laser beam onto the surface of the material. Depending on the laser power and the thickness of the stainless steel, the laser beam causes the material to melt or burn at the desired cutting point.

To perform stainless steel laser cutting, the laser beam must first be prepared. This is done by exciting laser-producing materials with electrical current or lamp radiation, and the resulting beam is reflected using mirrors in the device to focus the necessary energy for the cut. The beam is then directed to the targeted point through a lens located at the device’s head, which can reduce the beam size to 0.23 millimeters.

Advantages of Stainless Steel Laser Cutting

Stainless steel laser cutting has several advantages, including creativity in design,

flexibility, and the ability to create complex shapes, high precision, fast speed, low cost,

consistent cutting in repeated parts, high edge quality, minimal waste, no change in the

metal structure, the ability to cut in series, and the production of parts with uniform

thickness simultaneously, reducing multiple steps in the production process.

Using stainless steel laser cutting eliminates the formation of burrs at the cut edges,

which is the most significant advantage over older mechanical cutting methods. Because the

laser beam operates with precision and defined measurements, better order and accuracy can

be achieved in these cuts.

In general, the advantages of stainless steel laser cutting can be summarized as follows:

- Minimizing burr production

- Higher number of pieces can be cut

- Much lower costs

- High quality of laser-cut stainless steel work

- Minimizing waste production

- Capability to cut complex and intricate designs

Important Notes on Stainless Steel Laser Cutting

Conical Angle: Refers to the change in diameter of the hole along the thickness of the cut.

Burr Production: Naturally, the less burr produced after cutting, the better the final

quality, and the less need for secondary machining.

Kerf: Kerf defines the smallest radius that can be cut, which depends on the sheet thickness

and should be considered in design. For example, very sharp corners should have a radius at

least equal to the kerf. Additionally, the minimum holes that can be created in metal sheets

are dependent on the sheet's thickness. It is clear that the smaller the machine's kerf, the

better the ability to cut complex contours and fine, thick teeth.

Cutting Speed: This heavily depends on the capabilities of the machine and the laser beam's

power. The higher the power of the machine, the faster the cutting speed can be.

Surface Smoothness: One of the most important factors in cutting is the smoothness of the

surface and preventing oxidation, which can be achieved by combining various technologies

and properly adjusting control parameters such as gas type, gas pressure, cutting speed, and

laser beam power.

Cost of Stainless Steel Laser Cutting

Stainless steel is made by combining approximately 2% carbon with iron.

Stainless steel is used in many applications due to its high flexibility and resistance.

In the past, stainless steel was cut using saws or air gas, which often led to a reduction

in quality and required a significant amount of time for the cutting process.

However, today, with technological advancements, the challenge of cutting stainless steel

and other metals has greatly decreased. With stainless steel laser cutting machines, the

process is done easily, quickly, and with high-quality results.

If you want to ensure the quality of the cut, it’s better to check the amount of burr

produced during cutting; the less burr, the higher the quality of the work.

When calculating the cost, all aspects must be considered. Some may lower their prices to

attract customers, but hidden additional costs may make the final price higher for the

client.

To calculate the cost of metals, factors such as sheet thickness, batch size, part design,

material type, and gas used should be evaluated.

The material type and batch size are two key factors determining the price.