Sheet Bending

In various sheet metal processes, we encounter many situations where bending is required to achieve the desired shape, increase resistance to bending, prevent hand injury, create connections, and so on. The tools and machinery used for this purpose are diverse, and each can create specific bends.

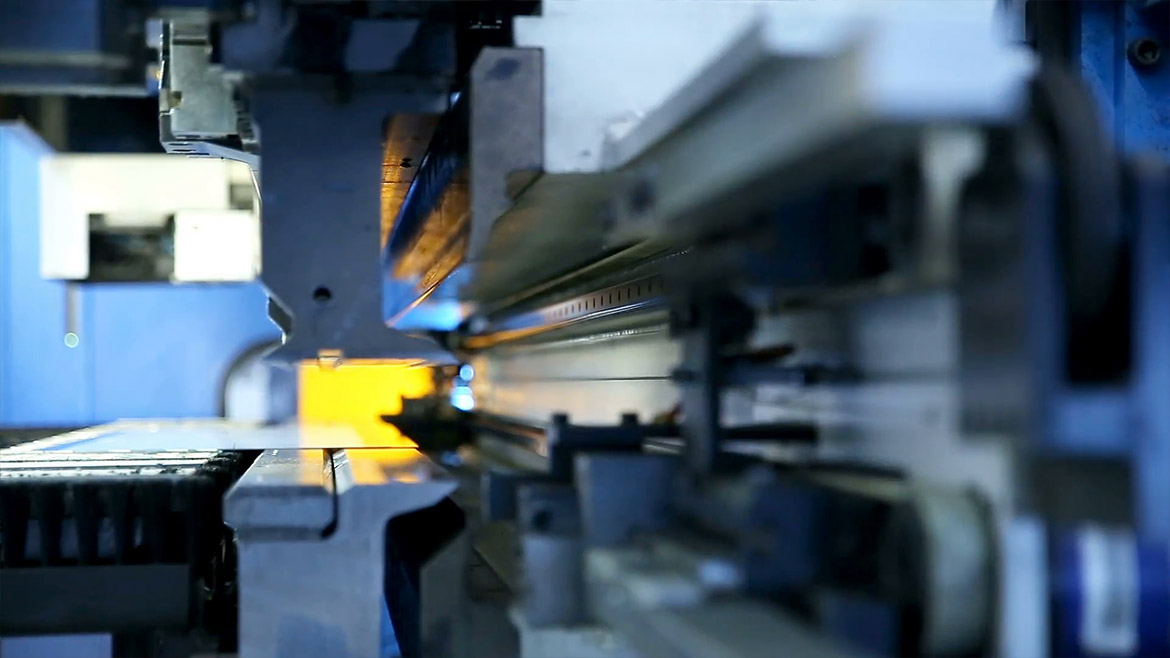

Bending at DM Laser Industrial Complex

The process of bending metal sheets is one of the most important manufacturing processes.

Bending is a process used to shape a flat sheet of metal into the desired form without

breaking or causing excessive thinning at specific points. Among the applications of this

process is creating curvature in a sheet; also, converting the sheet into a channel with

various cross-sections and, in some cases, circular shapes are some of the most common uses

of the bending process. Considering the growing applications of this process in various

industries such as automotive, aerospace, military, home appliances, etc., the importance of

this process becomes evident.

Nowadays, with technological advancements and the introduction of computers into production

and the use of CNC machines, products manufactured through the bending process are

significantly increasing in precision and quality.

DM Laser Industrial Complex is equipped with cutting and bending machines with a length of 4

meters. If the customer requires bending operations, after producing parts using the laser

cutting machine, based on the drawings and supported by the expertise of the DM Laser

Industrial Complex team, this process will be implemented.

Bending takes place after the laser cutting process on the material. Performing two stages

of production, including laser cutting at DM Laser Industrial Complex, optimizes

coordination, precision, speed, and the quality of the final product. DM Laser Industrial

Complex, with its experienced personnel, provides various services such as design and

modeling of parts, laser cutting, bending, and spot welding of various materials. So,

without any concerns, entrust all your industrial tasks to DM Laser Industrial Complex to

receive your final product with the best quality and in the most timely manner.

The bending unit of DM Laser Industrial Complex is equipped with European CNC bending machines in various sizes and tonnages. If bending operations are required, after producing parts with the laser cutting machine, the bending process is performed according to the drawings. Utilizing the most advanced technologies, the most precise sensors, and software, DM Laser Industrial Complex has become one of the strongest industrial complexes in the field of sheet metal bending. The use of shared software in both cutting and bending, as well as the ability to test the bending process with 3D simulation software, enables the user to control the bending process while examining the stretch and calculating it in sheet dimensions, thus applying the best method to achieve precise bending.

Thin Sheet Bending Services

Metal sheet bending causes the metal to undergo plastic deformation in the direction of the applied force, changing the sheet's geometry. Like other metal forming processes, in sheet bending, the shape of the sheet changes, but the volume of the metal remains unchanged. In some cases, the thickness of the sheet may change slightly. However, in most cases, this does not happen, and the thickness of the metal sheet remains constant. Bending metal creates tension and compression in the material. An important point to consider in bending is that the material properties play a crucial role. In some cases, cold bending is used, while in others, hot bending is performed at a working temperature.

Bending operations are typically carried out with a machine known as a press brake. Therefore, the bending process in the industry is also known as press brake forming. Press brakes are available in various sizes and capacities (from 20 to 200 tons). Each bending machine consists of an upper tool (punch) and a lower tool (die), with the metal sheet placed between these two tools. The sheet rests on the die and is held in place by jaws. The punch then moves downward, bending the sheet. In CNC bending machines, this force is generated by hydraulic jacks.

The bending angle is determined based on the depth of the force applied to the sheet. This

depth is carefully controlled to achieve the desired angle. The appropriate tool for bending

is selected based on product quality, type of sheet, sheet quality, and bending degree.

These tools are typically made from carbon steels.

CNC-controlled sheet metal bending is a manufacturing process performed using CNC press

brake machines. These machines can perform bending operations on sheets ranging from just a

few millimeters thick to parts several meters long on the largest industrial machines.

CNC Press Brake Machines Are Available in Two Types:

CNC press brakes, using their automatic navigation tools, provide precise forming and

bending services. CNC press brake machines are used for accurately shaping a wide range of

metal sheets in different materials, sizes, and thicknesses. Press brake forming processes

allow for high production volumes with minimal need for secondary finishing.

Generally, the sheet metal bending process depends on the type of workpiece, its dimensions,

and thickness. Additionally, parameters such as bend size, bend radius, bend angle, bend

curvature, and bend location on the workpiece are important factors in bending.

Types of Bending Methods

Generally, the parts that undergo the bending process feature one of the following types of

bends: V-shaped bending, L-shaped bending, or U-shaped bending (channel).

Curved Bending

Flange Bending

Direct Bending

V-Shaped Bending

This process requires the use of a punch and a die made of hardened steel. The punch's tip and the die's indentation are shaped in a V form. The die is placed on a specific base to withstand the bending force. The connection between the die and base is usually made with four bolts and two pins. One of the advantages of V-shaped bending is the simplicity of the mold and the ability to bend within a range of 0 to 90 degrees. To achieve a specific radius, the punch and die radius must be selected carefully. Today, auxiliary equipment such as rollers is used to reach a specified radius and increase the bending speed.

L-Shaped Bending

The aim of this process is to create a 90-degree bend using a punch-die pair. The die, similar to V-shaped bending, can be mounted on a base. To control the bending process, a pressure support, which also functions as a sheet holder, is used. The workpiece is positioned in the die such that its longer arm rests on the pressure support. When the punch lowers, the workpiece attaches to the pressure support and moves into the die, causing the smaller arm of the workpiece to become perpendicular to the larger arm.

U-Shaped Bending

The U-shaped bending die is made similarly to L-shaped bending. The difference is that two L-shaped bends are performed on the sheet, with equal forces applied from both sides of the bend in opposite directions. Advantages of this process include the simultaneous creation of two 90-degree bends with high precision. One limitation of this process is the opening of the bend due to springback.

Types of Bending Machines

Manual Bender

Simple Column Bender

Hydraulic and Mechanical Bending Press

Electric Bending Machine

Manual Bender

This machine is used for bends that are cornered and have limited curvatures.

The device is equipped with a base on which the lower jaw is mounted. The upper jaw uses a

mechanism for adjusting bolts, which can be used to secure sheets between the two jaws.

Another jaw, called the bending jaw, moves radially around the machine's axis, allowing the

sheet secured between the upper and lower jaws to be bent.

The machine includes a counterweight that neutralizes the weight of the bending jaw,

typically located at the end of the machine's axis.

The triple jaws, discussed earlier, have steel blades at their edges, which can be replaced

to produce various types of bends.

Using this sheet bending machine, you can bend steel sheets up to 3 mm thick, aluminum

sheets and alloys up to 6 mm thick, and copper and brass sheets up to 5 mm thick.

Simple Column Bender

These machines are produced in two models, with either a simple upper jaw or a jaw with

inserts, and are available in various sizes and lengths. In these machines, the metal sheet

to be bent is placed between the upper and lower jaws.

The upper jaw of these machines is movable and is lowered using a handle designed for this

purpose, pressing the metal sheet firmly against the lower jaw. A rotating plate is located

at the front of the machine, supported by two axles placed on either side in bearings. The

plate is housed within two vertically moving slides.

The rotating plate performs the bending process and is equipped with two weights. These

weights provide the bending force. The lower blade of the plate can be adjusted based on

different sheet thicknesses. By turning the wheel on the rotating plate, the plate moves

downward, and the machine is adjusted for the new thickness. The bending angle of the

rotating plate can also be adjusted to accommodate different sheet thicknesses.

With these benders, low-carbon steel sheets can be bent up to a thickness of 3 mm, aluminum

sheets up to 6 mm thick, and brass and copper sheets up to 5 mm thick.

Electric Bender

These machines offer better performance and efficiency compared to simple manual benders and

are produced in lengths ranging from one to six meters.

The components of an electric sheet bending machine include:

- Electric motor

- Reverse gear box for the machine's speed

- An electric motor that moves the upper jaw and related components, installed on the right

side of the machine's base

- The rotating plate and its components derive their bending force from the electric motor

- The power transmission equipment, which transmits force to the machine's moving parts, is

usually housed in the machine's base

- Finally, the control box, equipped with on/off switches for the motor and buttons for

precise stopping of the blades during bending, is mounted on the machine's body.

Press Bender

This machine is a type of manual or automatic press used to shape materials under pressure.

Typically, press machines are categorized by the following methods:

- By operation or mechanism: Hydraulic press, mechanical press, pneumatic press

- By application: Forging press, forming press, bending press, cutting press

- By structure and framework: Hammer press, screw press, gate press

Bending Costs

The cost of bending metals varies depending on several factors, including the material, type

of metal, volume, amount of work, time spent, and the method used.

In sheet metalworking, bending is employed to create curved shapes on metal pieces.

The bending capacity of metals varies significantly and depends on the amount of carbon

present in the metal.

To reduce the thickness and increase the length of metal without changing its width, the

rolling process is performed in either a cold or hot method.

A metal sheet with approximately 1/2 percent carbon can be bent in a cold state.

However, when the carbon content exceeds 1/2 percent, the metal must be bent in a hot state.

Metals like alloy steels, aluminum, copper alloys, stainless steel, and magnesium alloys are

produced during hot bending.

The approximate cost per bending strike ranges from 4,000 to 10,000 Toman, depending on the

complexity of the design. It is advised to consult with DM Laser consultants before placing

an order.

| Variable | Description |

|---|---|

| Factors affecting cost | Material type, metal type, work volume, amount of work, time spent, method used |

| Bending capacity of metals | Varies depending on the carbon content in the metal |

| Rolling process | Performed in cold and hot methods |

| Cold bending conditions | Metal with approximately 1/2 percent carbon |

| Hot bending conditions | When carbon content exceeds 1/2 percent |

| Types of metals suitable for hot bending | Alloy steel, aluminum, copper alloys, stainless steel, magnesium alloys |

| Cost per bending strike | 4,000 to 10,000 Toman, depending on design complexity |

What Applications Use Bending?

One of the processes that has significantly advanced industrial production is metal bending.

Metal bending is used in the production of metal boxes in industries such as electronics,

agriculture, livestock, electrical, food, and many others.

Metal bending is a highly efficient and quick method for creating various types of boxes.